Read Reviews

The Best Air Compressors

-

Best for inflating tyres - AstroAI Digital Tyre Inflator

-

Best low noise air compressor - Hyundai HY7524 24 Litre Ultra Silent Air Compressor

-

Best for home use - Hyundai HY5508 8 Litre Silenced Air Compressor

-

Best portable air compressor - WindGallop Digital Car Tyre Inflator

-

Best air compressor with upright design - Einhell TC-AC 200/30/8 30L Air Compressor

-

Best compressor for paint spraying - Dealourus Portable 50 Litre Air Compressor

-

Best for power - Hyundai Electric HY3050V 50L Air Compressor

-

Best compact air compressor - Parker Brand 24 Litre Air Compressor

-

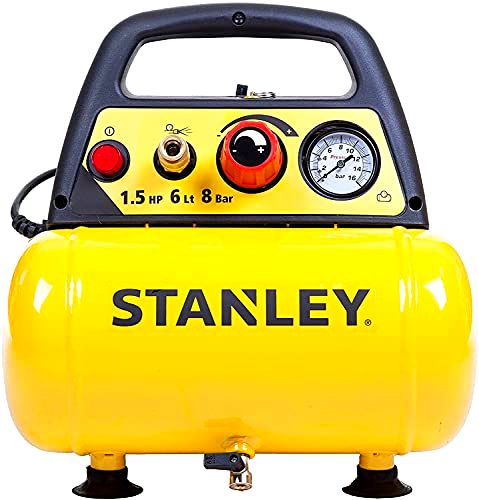

Best for hobby work - Stanley DN200/8/6 6L Air Compressor

-

Best air compressor for beginners - ORAZIO 241184 Low Noise Silent Air Compressor

Air Compressor Reviews

1. AstroAI Digital Tyre Inflator[ SAVE 30% ]

Best for inflating tyres

- Reinflating flat tyres is as simple as plugging in, selecting the required pressure, and pressing the power switch. The digital pressure gauge will turn itself off at the correct level.

- The four little legs on the bottom of the compressor have soft rubber feet. This helps to reduce unwanted vibration and noise when the pump is running.

- I’m a big fan of the valve extender accessory included with this compressor. It gives an essential bit of extra reach and means you only use the Schrader valve when necessary.

- The large backlit LCD screen shows you the pressure you’re inflating to in several different units. Simply press the “M” button to toggle between PSI, kPa, BAR and KG/CM.

- Unlike the WindGallop air compressor, there’s no onboard power cable storage on this device. You’re stuck with wrapping up the cord and hoping it doesn’t get tangled.

- Compared with the large workshop air compressors on my list, don’t expect this tool to power air tools or inflate large lorry tyres. The onboard motor isn’t powerful enough.

- Like the WindGallop compressor, the motor in this device isn’t designed to run for long periods. To avoid overheating, only run it for less than 15 minutes at a time.

- Air Tank Size

- n/a

- Maximum Pressure

- 7 bars

- Motor Power

- unknown

- Flow Capacity

- 35 litres per min

- Sound Level

- unknown

- Weight

- 1.0kg

- Air Tool Kit

- No

- Build Quality

- 4

- Performance

- 4

- Ease of Use

- 3

- Value for Money

- 3

The ideal gadget to throw in the back of your car for emergencies, or even for a spot of camping, the AstroAI digital portable tyre inflator is a seriously handy tool. Designed specifically for in-car use, it can also pump up just about anything thanks to the accessory kit that comes with it.

The lightweight and easily transportable compressor unit barely takes up any room in your car boot, but it can reinflate a standard-size car tyre from flat in just a few minutes. Dialling in a specific tyre pressure takes just a few button presses, and the compressor shuts off automatically when the desired target is met. It’s incredibly easy to use and might save your skin some day!

There’s a 10-lumen onboard LED work light for working in the dark, and you get a decent length of power cable to plug into your car’s 12V power system as well. And for pumping up anything other than a car tyre, there’s a handy little accessory kit included with the compressor.

Did you find this review helpful?

2. Hyundai HY7524 24 Litre Ultra Silent Air Compressor

Best low noise air compressor

- Compared to the big Hyundai HY3050V compressor, this is much quieter to operate. You won’t mind too much when the motor kicks in to refill the tank.

- Oil-free air compressors are much easier to use straight from the box. The pistons are permanently lubricated with Teflon, so no more oil change issues!

- The rubber anti-vibration pads do a good job of keeping down the noise levels during operation.

- For some reason, the second air line is almost impossible to get at. The connector points directly at the motor and there’s not enough clearance for most accessories.

- You can only build up a maximum air pressure of 7 bar. Compared with the similar size ParkerBrand, that’s one bar less. It makes a lot of difference for some applications.

- Some users have had problems putting the compressor together at first. There’s not much to assemble, but the manual isn’t particularly clear.

- The 24 litre tank isn’t big enough for constant air-hungry tasks like paint spraying. Compared with the big Dealourus 50 litre compressor, it’s small.

- Air Tank Size

- 24 litres

- Maximum Pressure

- 7 bars

- Motor Power

- 0.75kW

- Flow Capacity

- 147 litres per min

- Sound Level

- 60dB

- Weight

- 22.0kg

- Air Tool Kit

- No

- Build Quality

- 5

- Performance

- 4

- Ease of Use

- 4

- Value for Money

- 4

The HY7524 oil-free air compressor from South Korean industrial titans Hyundai makes use of a 750 Watt, 1-hp motor to drive the air pressure up to an impressive 7-bar that puts out 5.2 cfm. Not bad for a smaller machine. It’s still enough for reasonably air-hungry tasks you might get up to in your home workshop.

It comes with a 24-litre tank and there’s only 22 kg to lug around. This compressor bridges the gap between being very portable and holding enough air to get bigger jobs done. I like that it’s an oil-free compressor as well. There’s no messing around with messy lubricants to get this machine to work properly.

The idea of “silent” air compressors is a bit of a mystery to me. This compressor puts out just 60 dB though. That’s equivalent to a conversation in a restaurant, so it’s quite impressive compared to much louder air compressors.

They haven’t included an accessory pack or airline though, so you’ll have to buy those bits separately.

Did you find this review helpful?

3. Hyundai HY5508 8 Litre Silenced Air Compressor

Best for home use

- Even though this is a small and portable air compressor, it can still put out 4 cfm. That’s more than enough for air nailers and polisher tools.

- Compared with the Dealourus air compressor, this is an extremely quiet machine. It’s the sort of thing you could use at home without annoying everyone too much!

- Unless you really need to run air-hungry tools or spray paint, don’t waste space with a huge air tank. The 8 litre tank on this compressor is powerful and compact for smaller spaces.

- There are no wheels on this compressor, just rubber feet. It’s great for staying in place in a workshop, but not ideal if you need to move it around a lot.

- Compared with the larger Hyundai HY7524, you only get one airline outlet. I’m a big fan of having more than one, to avoid changing Euro connectors all the time.

- Don’t expect this air compressor to blow up tractor tyres or run air-hungry tools like orbital sanders. The 4 cfm maximum output is not enough for those sorts of jobs.

- Air Tank Size

- 8 litres

- Maximum Pressure

- 7 bars

- Motor Power

- 0.55kW

- Flow Capacity

- 113 litres per min

- Sound Level

- 60dB

- Weight

- 15.0kg

- Air Tool Kit

- No

- Build Quality

- 5

- Performance

- 4

- Ease of Use

- 5

- Value for Money

- 4

The South Korean manufacturing experts Hyundai make an impressive range of air compressors. The HY5508 is an extremely compact and lightweight bit of kit that you can take with you wherever you need to go.

Boasting a featherlike 15 kg weight, it’s still got a serious amount of power underneath the bonnet. The 0.55 kW or 0.75 hp motor might seem small but it can fill the 8-litre tank quickly. It’s not the sort of compressor you’d use for paint spraying large areas, but it’s ideal for running an air nailer on site.

For this size air compressor, I’m impressed with the 7 bar maximum air pressure it can build. This is a capable air compressor that might not be as powerful as a full-sized compressor with a large 2 hp motor, but you can literally pick this one up and walk off with it.

What makes this possibly the best air compressor for home use are the low noise levels. When the motor’s running it puts out just 60 dB. That’s not very loud. It makes it an ideal hobbyist compressor setup when noise needs to be kept to a minimum.

Did you find this review helpful?

4. WindGallop Digital Car Tyre Inflator

Best portable air compressor

- Keeping the cable and hose clean and tidy is easy. They’re both stored inside the unit when not in use. It’s a handy solution to the mass of cords these types of compressors have.

- WindGallop have included a decent selection of valve adapters for different situations. It’s good for inflating things like air mattresses, sports balls, bike tyres, and rubber dinghies.

- The backlit LCD screen allows you to cycle through different units of air pressure. Alongside the standard PSI and BAR measurements are KPA and KG/CM. Not a bad thing to have.

- Having a pair of large and powerful LED lights in the boot of your car is a handy thing to have. Making repairs or pitching a tent in the dark is no one’s idea of fun after all!

- Compared with the heavy duty compressors on my list, you can’t expect a little 12V device like this to inflate large tyres. It’s ideal for cars and bikes, but not large SUVs or lorries.

- Be aware that although 3 m of power cable is quite long, you might still struggle to reach the tyres on some long estate cars. The 50 cm long air hose doesn’t add much reach either.

- If you’re planning on inflating things like boats, bear in mind that this compressor has a duty cycle of 10 minutes on, then 10 minutes off. Don’t exceed this or it will overheat.

- Air Tank Size

- n/a

- Maximum Pressure

- 7 bars

- Motor Power

- unknown

- Flow Capacity

- unknown

- Sound Level

- unknown

- Weight

- 0.9kg

- Air Tool Kit

- No

- Build Quality

- 4

- Performance

- 3

- Ease of Use

- 5

- Value for Money

- 5

There’s nothing worse than trying to guess the air pressure in your tyres. Old-fashioned analogue gauges on tyre inflators leave too much to the imagination, so the clever minds at WindGallop have taken the guesswork out of the situation. Their digital car tyre inflator is an essential piece of kit. You can keep your tyres pumped up, reinflate a flat, or use it to pump up just about anything on a trip to the beach.

This futuristic-looking digital compressor is a lot more than a basic foot pump for your car or bike tyres. All you need to do is set the required pressure using the little buttons under the display, connect the hose to your target valve, and press the power button. The compressor will do the rest and shut off automatically when it reaches the right pressure.

The power comes from your car’s 12V power supply and plugs directly into the “cigarette lighter” socket. You get a little over 3 m of power cord, and 50 cm of air hose that should reach almost anywhere you need it to. And if you get a flat tyre in the dark, simply press the lightbulb button to activate the pair of large LED lights on the front side.

Did you find this review helpful?

5. Einhell TC-AC 200/30/8 30L Air Compressor

Best air compressor with upright design

- The upright design is a game changer for a small workspace. Compared with the enormous footprint on the Dealourus compressor, the Einhell can fit just about wherever you need it.

- Compared with the 24 litre tank on the Orazio 241184, the Einhell has more air to play with. Having 30 litres means you can get a bit more work done without the motor kicking in.

- Compared to the substandard manuals provided with the Orazio 241184, the one that Einhell provide is great. You get large pictures and a clear setup guide.

- Even though it’s not as loud compared to the big Hyundai HY3050V, it still puts out 77dB during use. That’s loud for a workshop setting.

- There’s only one air outlet. Compare it with the twin outlet valves on the ParkerBrand, and you’ll need to switch every time you change air tools.

- One of the drawbacks of a vertical air compressor is that it can topple over. If you tug on the airline, you can’t drag it around. Not that you should anyway!

- Air Tank Size

- 30 litres

- Maximum Pressure

- 8 bars

- Motor Power

- 1.1kW

- Flow Capacity

- 200 litres per min

- Sound Level

- 77dB

- Weight

- 18.0kg

- Air Tool Kit

- No

- Build Quality

- 4

- Performance

- 4

- Ease of Use

- 4

- Value for Money

- 4

German engineering firm Einhell have built themselves a solid reputation for honest power tools that won’t completely empty your wallet. The TC-AC 200/30/8 air compressor is a solid and dependable workshop tool that takes up less room than the competition.

Making use of a 1.1 kW motor, the compressor can build up to 8 bar in the tank. The output is close to 6 cfm, or 165 litres per minute (lpm). It’s perfectly suited to DIYers because it’s a low-maintenance oil-free system as well.

What I like about this air compressor is its upright design. Most air compressors sit horizontally, taking up a lot of floor space. The Einhell has a much smaller footprint while still performing well against the competition. This makes it an ideal tool for smaller workshops.

At just over 18 kg in weight, it’s reasonably portable. You can make use of the large wheels and higher handle for transporting without hurting your back. The large 30-litre air capacity is welcome because the motor is loud when in use.

Did you find this review helpful?

6. Dealourus Portable 50 Litre Air Compressor

Best compressor for paint spraying

- Getting the largest air tank you can cope with is a great idea. You can get more work done without the motor kicking in and it’s more efficient for jobs like spray painting.

- For a 50 litre air compressor, it’s nice and light at just 29 kg. Compared to the Hyundai HY3050V, you get the same capacity for a lot less weight.

- When the motor kicks in, it’s not incredibly loud. At 70 dB it’s quieter than the Hyundai HY3050V by a whopping 20 dB. That’s not much louder than a home vacuum cleaner.

- For the money, this air compressor ticks all the right boxes. Good capacity, accessories and it’s not overly heavy for the size.

- The electric motor isn’t as capable compared to the one on the Hyundai HY3050V. You get half a horsepower less. It’s going to take longer to refill the air tank each time.

- With just over 271 litres per minute, the airflow is a lot less than the Hyundai HY3050V’s 396 litres per minute. You’re not going to be able to spray as much paint or blast as much air.

- This air compressor’s never going to be as portable compared with the lightweight Hyundai HY5508. You get wheels to move it around, but it’s still a very heavy piece of equipment.

- Although you get a decent set of accessories, some users have complained that they’re not the best quality. You’ll end up replacing them before long.

- Air Tank Size

- 50 litres

- Maximum Pressure

- 8 bars

- Motor Power

- 1.5kW

- Flow Capacity

- 270 litres per min

- Sound Level

- 70dB

- Weight

- 29.0kg

- Air Tool Kit

- Yes

- Build Quality

- 5

- Performance

- 4

- Ease of Use

- 5

- Value for Money

- 5

Sporting a large air tank, powerful motor, and extensive accessory kit, the Dealourus 50L air compressor is a serious piece of kit.

With a 2.5 horsepower or 1.5 kW motor under the bonnet, this is a reliable and powerful air compressor. I’m impressed by the 50-litre air tank because it means you’re going to spend less time running the motor and more time blasting air.

The huge tank capacity makes this a great air compressor for paint spraying. It’s more than capable of dealing with air-hungry applications compared to air compressors with smaller air capacity.

Probably my favourite thing about this air compressor is the weight. It weighs less than 30 kg and comes with a pair of large wheels and a handle for moving it around to where you need it. That’s an impressive power-to-weight ratio.

I’m impressed by the accessory kit as well. You get a tyre inflator with an accurate pressure gauge, an air blowing gun, a paint spray gun, and an oil spraying gun. There is also four metres of quality spiral hose. It’s the ultimate value-for-money air compressor kit if you ask me.

Did you find this review helpful?

7. Hyundai Electric HY3050V 50L Air Compressor

Best for power

- A quality air compressor kit from one of the biggest names in South Korean engineering. The whole kit oozes quality.

- The 2.2 kW or 3 hp engine is hefty and is more than enough for DIY jobs. It can comfortably deal with air-hungry jobs and fills the 50 litre tank quickly compared with the Dealourus.

- The electric motor isn’t just big, but it runs at a high speed too. It’s tuned to 2,850rpm, to help it make short work of filling the tank.

- The air flow capacity is unbeatable for this class of air compressors. 396 litres per minute is more than enough air to power tools, run paint sprayers or inflate the biggest tyres.

- The air tools included with the Hyundai compressor are of particularly good quality. They're more than enough for a beginner to try out all the things you could do with an air compressor.

- As you might expect from powerful air compressors with a 3 hp motor, this one is very loud. Hyundai have rated it at 93 dB, but it feels like more than that when it catches you off guard!

- Several users have complained about the poor instructions that are supplied with the compressor. For such a powerful bit of kit, a better manual would be preferred.

- 45 kg is heavy for an air compressor. Unless you run long air lines, it’s going to be a pain to manoeuvre it to the workpiece. Compared to the 15 kg Hyundai HY5508 it’s a beast!

- This isn’t an air compressor aimed at the casual DIYer. It’s too expensive, heavy, and large for casual users.

- Air Tank Size

- 50 litres

- Maximum Pressure

- 8 bars

- Motor Power

- 2.2 kW

- Flow Capacity

- 396 litres per min

- Sound Level

- 93dB

- Weight

- 45.0kg

- Air Tool Kit

- Yes

- Build Quality

- 5

- Performance

- 5

- Ease of Use

- 4

- Value for Money

- 4

Probably more famous internationally for their cars, Hyundai are one of South Korea’s biggest engineering firms. They also happen to make probably the best air compressor that I’ve had a chance to try out.

The HY3050V portable air compressor makes use of a powerful 2.2 kW 3 hp motor to fill the large 50-litre tank up to 8 bar. And because it’s got a direct drive pump, you can expect it to be a reliable air compressor that will last for years. Putting out 14 cubic feet per minute (cfm), it’s more than powerful enough for any home DIY task.

The 50-litre tank is a real advantage if you want to get into air-hungry jobs like paint or adhesive spraying. It means you can spend more time working and less time listening to the motor run to refill the tank.

Weighing in at 45 kg, it’s a good thing that this air compressor comes complete with a sturdy pair of wheels on the back. The tubular steel handle on the front helps to make it portable as well as sturdy.

What makes this Hyundai air compressor stand out though is the accessory kit. Hyundai have included a decent quality set of air tools. A standard blowing head, liquid sprayer with tank, paint spray gun, inflator with pressure gauge, and airline. You can get to work straight away!

Did you find this review helpful?

8. Parker Brand 24 Litre Air Compressor

Best compact air compressor

- ParkerBrand have opted for a more powerful motor on this compressor compared with the Hyundai HY7524.

- The 1.5 kW electric motor runs at 2,850 rpm, which makes the tank fill much faster.

- The air flow capacity is seriously high for electric air compressors of this size. You get close to 10 cfm, which is great for when you need a lot of air quickly.

- Don’t underestimate the noise this compressor makes. You should wear ear defenders if you’re planning on using it often. Compare it to the Hyundai HY7524 and it’s extremely loud.

- It’s a shame this compressor doesn’t come with any accessories. Compared with the Hyundai HY3050V, you need to get out there and buy your own airline and guns.

- Even though it makes the overall size of the compressor smaller, I still can’t work out the mini handle. It would be much more useful if it could extend for easy transport.

- Air Tank Size

- 24 litres

- Maximum Pressure

- 8 bars

- Motor Power

- 1.5kW

- Flow Capacity

- 270 litres per min

- Sound Level

- unknown

- Weight

- 26.5kg

- Air Tool Kit

- No

- Build Quality

- 4

- Performance

- 4

- Ease of Use

- 4

- Value for Money

- 4

A family-owned tool business based in Lincolnshire, ParkerBrand design and make an impressive range of power tools and workshop equipment. Their 24-litre air compressor is one of the best compact air tools that I’ve tried out and proves to be serious value for money.

With a 1.5 kW, 2.5 hp motor this air compressor puts out 9.6 cfm. It’s enough for smaller spraying jobs but it’s not the most efficient bit of kit on the market. It can pressurise the tank to just under 8 bar, which is enough for most DIYers.

At 26.5 kg, it’s a little heavier compared with the Hyundai HY7524, but the wheels make it just as portable. The handle’s a bit shorter though, which makes it a bit more awkward to manoeuvre. And don’t expect the larger motor to be quiet either, it’s quite noisy when in operation.

Did you find this review helpful?

9. Stanley DN200/8/6 6L Air Compressor

Best for hobby work

- This is an incredibly compact little air compressor. If you’re a hobbyist and need an air compressor for airbrushing or light duty nailing, you can’t go wrong.

- Portable air compressors like this one are extremely light weight. This one weighs just 9 kg, making it ideal for taking with you to the job.

- The motor runs at an unbelievably quick 3,400rpm. Even though it’s not the biggest, it works extremely hard.

- It’s almost hard to believe how loud this air compressor is. At 97 dB, it puts out the same noise levels as the huge 3 hp motor on the Hyundai HY3050V.

- For some users, the 6 litre tank just isn’t enough. You’re not going to run many air tools or spray paint with this compressor. The motor will be forever refilling the tank up.

- Some users have complained that the air compressor is supplied with the incorrect plug. Some seem to be shipped without the correct 3-pin UK plug.

- Air Tank Size

- 6 litres

- Maximum Pressure

- 8 bars

- Motor Power

- 1.1kW

- Flow Capacity

- 200 litres per min

- Sound Level

- 97dB

- Weight

- 9.0 kg

- Air Tool Kit

- No

- Build Quality

- 4

- Performance

- 4

- Ease of Use

- 5

- Value for Money

- 4

One of the biggest names in DIY, Stanley have been making reliable kit for more than 170 years, a pedigree that’s hard to match by any rivals.

The DN200/8/6 compressor is a small, benchtop tool that isn’t meant to rival large compression tanks. It’s more suited to small DIY jobs unless you want to listen to the motor building up air pressure every few minutes.

With a 1.1 kW, 1.5 hp electric motor, you can fill the 6-litre capacity tank up to a useful 8 bar of air pressure and output just over 5 cfm. The advantage of this mini air compressor is that it’s extremely light and portable. It doesn’t come with wheels because it really doesn’t need them. Weighing just 9 kg, you should be able to move it where you need it without breaking a sweat.

The oil-free construction means there’s minimal fiddling around and helps to keep everything nice and simple. Provided you don’t need huge amounts of air and are only using this air compressor for fine or hobby work, you won’t be disappointed.

Did you find this review helpful?

10. ORAZIO 241184 Low Noise Silent Air Compressor

Best air compressor for beginners

- Compared with the similar-sized Hyundai HY7524, this is a bargain. If you’re just getting into air tools, it’s the best beginner’s air compressor.

- You can build the pressure up to the full 8 bars necessary for a lot of jobs. You can get more air pressure out of this machine compared with the Hyundai HY7524.

- At just 65 dB, this is a quiet machine compared with the incredibly loud Hyundai HY3050V. Your neighbours will thank you for it too!

- I’m a fan of oil-free compressors. Remembering to keep oil levels topped up is just another thing to get wrong. There’s a lot less maintenance required with this tool.

- Some users had issues with product quality control. Some have been shipped out without being superbly finished. You should inspect the compressor before first use.

- The manufacturer recommends changing the Teflon piston rings, but don’t sell them directly. You’ll need to source them yourself to keep the compressor running well.

- The user manual is not easy to follow. Unless you’re familiar with how to put together an air compressor, you might struggle at first.

- Air Tank Size

- 24 litres

- Maximum Pressure

- 8 bars

- Motor Power

- 0.8kW

- Flow Capacity

- 133 litres per min

- Sound Level

- 65dB

- Weight

- 22.0kg

- Air Tool Kit

- No

- Build Quality

- 4

- Performance

- 4

- Ease of Use

- 4

- Value for Money

- 4

ORAZIO sell lots of different filters, regulators, and accessories for their air compressors. The 241184 low-noise air compressor is a reliable, lightweight machine that makes transporting it around nice and easy.

Although this smaller air compressor can’t put out as many cubic feet per minute of air as other air compressors, it’s wonderfully quiet. It makes it ideal for light workshop use when air pressure requirements are less.

For the money, you get a 0.8 kW or 1.1 hp motor that can put out a reasonable 4.7 cfm. It comes in a lightweight compressor package weighing just 22 kg. The little wheels on the back mean you can manoeuvre it around quite easily as well.

What sets the Orazio 241184 apart from the competition is how quiet it is when in operation. At just 65 dB, you could have a conversation with someone next to it when it’s running. Not bad at all.

Did you find this review helpful?

Compare Product Features

Use the dropdown to sort the table by the feature you want to see.

AstroAI Digital Tyre Inflator

- 3.5

- n/a

- 7 bars

- unknown

- 35 litres per min

- unknown

- 1.0kg

- No

Hyundai HY7524 24 Litre Ultra Silent Air Compressor

- 4.3

- 24 litres

- 7 bars

- 0.75kW

- 147 litres per min

- 60dB

- 22.0kg

- No

Hyundai HY5508 8 Litre Silenced Air Compressor

- 4.5

- 8 litres

- 7 bars

- 0.55kW

- 113 litres per min

- 60dB

- 15.0kg

- No

WindGallop Digital Car Tyre Inflator

- 4.3

- n/a

- 7 bars

- unknown

- unknown

- unknown

- 0.9kg

- No

Einhell TC-AC 200/30/8 30L Air Compressor

- 4

- 30 litres

- 8 bars

- 1.1kW

- 200 litres per min

- 77dB

- 18.0kg

- No

Dealourus Portable 50 Litre Air Compressor

- 4.8

- 50 litres

- 8 bars

- 1.5kW

- 270 litres per min

- 70dB

- 29.0kg

- Yes

Hyundai Electric HY3050V 50L Air Compressor

- 4.5

- 50 litres

- 8 bars

- 2.2 kW

- 396 litres per min

- 93dB

- 45.0kg

- Yes

Parker Brand 24 Litre Air Compressor

- 4

- 24 litres

- 8 bars

- 1.5kW

- 270 litres per min

- unknown

- 26.5kg

- No

Stanley DN200/8/6 6L Air Compressor

- 4.3

- 6 litres

- 8 bars

- 1.1kW

- 200 litres per min

- 97dB

- 9.0 kg

- No

ORAZIO 241184 Low Noise Silent Air Compressor

- 4

- 24 litres

- 8 bars

- 0.8kW

- 133 litres per min

- 65dB

- 22.0kg

- No

How to Choose The Best Air Compressor

Having compressed air on tap is remarkably useful. You can use it to power a huge range of air tools and do away with expensive batteries, reinflate car tyres without having to go to the petrol station and blow the dust out from the tightest spots with ease.

Air Compressor Tank Size

This is probably the most important thing to consider before buying a pneumatic tool. If you’re planning to run power tools for long periods of time, you want to get the biggest air storage tank you can fit in your workshop. With a large tank, you can build up good air pressure and expel air for ages without having to listen to a noisy motor run and refill the tank. If you’re planning to use pneumatic tools more sparingly, save your money and stick with a smaller tank.

Air Compressor Motor Size

To fill up your tank and build enough air pressure for working, you need a decent size electric motor. Essentially, the bigger the motor is, the less time you have to listen to it refilling the tank, and the less energy it will have to use to get there.

Air Compressor Noise Levels

As you can probably already tell, one of the least desirable aspects of using air compressors is the noise. When the electric compressor motor kicks in you can expect it to reach a deafening 90 dB, which will require ear defenders to avoid hearing damage. Although advertised as “silent”, some of the best air compressors still boast a rating of around 60 dB.

Oil and Oil-Free Air Compressors

An air compressor works by using an electric motor to drive a pump. The pistons inside that pump need lubrication to work, and in an oil air compressor, this is liquid oil like you’d find in your car engine. An oil-free pump doesn’t require compressor oil but uses what’s known as permanent lubrication on the pistons, usually some low-friction material like Teflon. Air compressors with oil-free pumps need a bit more maintenance but are usually more durable.

Air Compressor FAQs

It depends on what you want to do with your air compressor. If you want to convert all your workshop power tools to pneumatic tools, then get the biggest tank you can fit. If you’re only occasionally using compressed air as a tyre inflator, blow around a bit of dust or drive a few brad nails, then you can get away with a smaller and more portable air storage tank.

Having compressed air is great. If you spend a lot of time working on your car, then you can use it as a tyre inflator or drive a polisher, or if you’re a keen DIYer you can run a nail gun without lugging around a heavy battery-powered nailer. Cleaning up sawdust is another handy use for an air compressor, but I find it’s the only way I can get the crumbs out from the nooks and crannies in my car.

The list of air tools and accessories you can get is enormous. The obvious pneumatic tools are nail guns and paint sprayers, but you can use air to power tools like drills, sanders, angle grinders, shears, and saws if you like.

Share